Following are the top questions and answers expcted in Boiler inspector and BOE interview exams

1-When did the recent Amendment of provisions (Jan Vishwas) act take place?

The Jan Vishwas act i.e amendment of Provisions took place in 2023

2-What do you understand by the name IBR act and regulations?

IBR stands for Indian Boiler Regulations, which are a set of rules formulated under the Indian Boilers Act, 1923. These rules govern the design, manufacture, installation, operation, and inspection of boilers in India to ensure safety and efficiency.

The Indian Boilers Act, 1923 = The law (legal authority)

The Regulations are the detailed rules and technical requirements framed under the Act 1923.

The Indian Boiler Regulations (IBR) = The rule book (technical guidelines) created under that law

3-How many Regulations and Acts are there as per IBR?

As per IBR 1950 there are around 626 nos of regulations and as per IBR Act-1923 there are around 35 nos of acts.

4-Which state in India is not applicable for IBR act-1923?

It is Jammu and Kashmir.

5-To which Boilers these regulations do apply?

IBR regulations shall apply to all the Boilers including those working on the principles of natural circulation, forced circulation & forced flow with no fixed steam and water lines

6-According to the IBR regulation No.2, what is the Appraisal committee?

Appraisal committee constituted by Central Boilers Board (CBB) consists of;

1- Chairman- Technical Advisor (Boilers)

2-Members-Five chief inspectors or Director of Boilers from states (Including chief inspectors or Director of Boilers of the states)

3-Five members from board representing Central government or Bureau of Indian standards or Boiler and Boiler component manufacturers or National Laboratories or Engineering consultancy agencies or users of Boilers & other interests.

7-Who does nominate the members of Appraisal committee?

Secretary or Central Boilers Board (CBB) nominates the Appraisal committee members

8-As per the IBR regulation No.2, what do you mean by the Design pressure of The Boiler?

Design pressure for the Natural circulation or assisted circulation Boilers, the maximum allowable working pressure in the steam drum of the Boiler

And, for Once through forced circulation Boilers, the maximum allowable working pressure at the final super heater steam outlet.

9-As per the IBR regulation No.2-definitins, what do you mean by Economiser?

Economiser is the part of feed pipe that is wholly or partially exposed to the action of the flue gases for the recovery of waste heat from it.

10-What is the significance of IBR regulation No.4?

IBR regulation No.4 is for Procedure for Recognition of;

1.Competent Authority,

2.Inspecting authority,

3.well known material testing Laboratory,

4.Well known steel maker,

5.Well known foundry/forging,

6.Well known Tube/Pipe Maker

7.Well Known RLA organisation

11-A Boiler of working pressure 109 kg/cm2 and operating since last 25 years, then as per IBR No.7 at what pressure boiler should be operated from 26th Year?

As per IBR-7, Boiler operating pressure should be reduced by 5% after 25 years of operation. That is A boiler operating at 109 kg/cm2 pressure should be operated at 103.55 kg/cm2 after 25 years.

Boiler operating pressure reduction chart

| Age of the Boiler (From the date of first use in years | 25 | 35 | 45 | 50 | 60 | 70 | 80 | 90 | 100 |

| % of reduction in working pressure | 5 | 10 | 15 | 20 | 30 | 40 | 50 | 60 | 70 |

12-What are the grades of carbon steel based on the conformity to tensile strength?

1-37-45 kgf/mm2

2-42-50 kgf/mm2

3-47-56 kgf/mm2

4-52-62 kgf/mm2

13-What is the maximum allowable percentage of Sulphur or Phosphorous in steels used in Boilers?

As per IBR No.10 (Chemical Analysis), a steel should not contain Sulphur or Phosphorous > 0.05%

When the material is required for flame cutting or welding, then carbon content should not exceed 0.3%

14-What is the silicon content of material which is intended for service temperature > 350 deg C?

It is around 0.10%

15-What are the tests performed on Boiler carbon steel tubes whose design temperature < 454 deg C?

As per IBR regulations 38 to 42, following tests are performed on carbon steel tubes

1-Tensile test

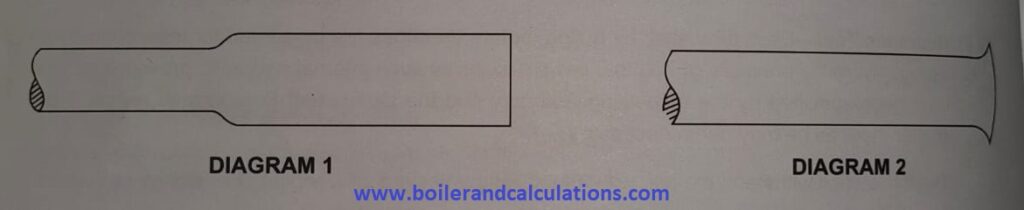

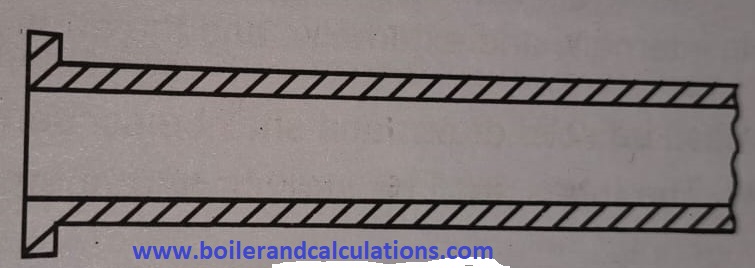

2-Flattening test

3-Expanding or Flaring test

4-Hydraulic test

As per IBR regulations 44 to 46, following tests are performed on carbon steel pipes

1-Tensile test

2-Bend test

3-Flattening test

4-Expanding or Flaring test

5-Hydraulic test

16-What are the tests performed on Boiler copper/brass tubes?

As per the IBR regulation No.35 following tests are carried out on copper & brass tubes

1-Tensile test

2-Bulging or drifting test

3-Flanging test

4-Flattening & double over test

5-Hydraulic test

17-Explain the Bulging or drifting test carried out on carbon steel tubes.

Any copper or brass tube should stand bulging or drifting cold tests without showing either crack or flaw until the outside diameter of the bulged or drifted part measures not less than 25% more than the original diameter of the tubes.

18-Explain the Flanging test carried out on copper & brass tubes

The copper or brass test piece shall withstand flanging (cold test) without showing either crack or flaw until the diameter of the flange measures not less than 40% more than the original diameter of the tubes

19- Explain the Flattening & Doubling over test carried out on copper & brass tubes

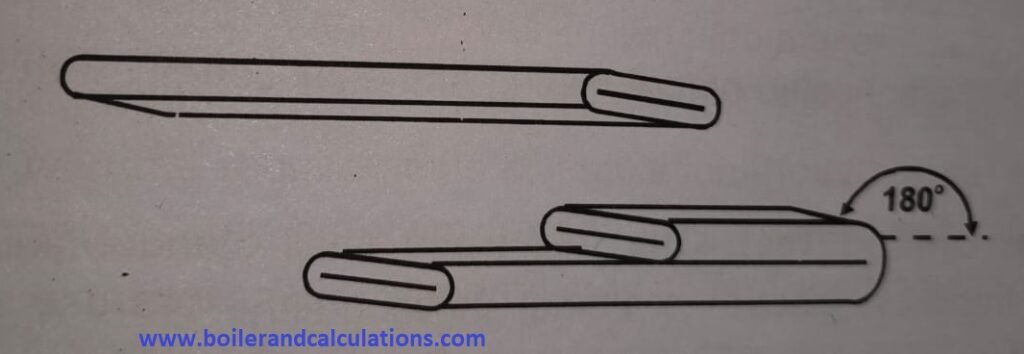

Test pieces of Copper and brass should withstand both flattening & doubling over test in both cold & hot condition without showing any crack or flaw.

In this, a test piece shall be flattened down until the interior surfaces of the tube meet and then double over on itself. That is flattened tube is bend through an angle 180 deg, the tube should be bent at right angles to the direction of the length of the tube.

20-What are the major contents of Carbon steel as per IBR regulations?

Major contents of the carbon steel are Carbon, Manganese, Silicon, Sulphur & Phosphorus

21-Write down the chemical composition of Carbon steel Tubes?

| Steel Grade | C% | Mn% | Si% | S% | P% |

| TA | 0.06-0.18 | 0.27-0.63 | 0.25 Max | 0.035 Max | 0.035 Max |

| TB | 0.27 Max | 0.93 Max | 0.1 Min | 0.035 Max | 0.035 Max |

| TC | 0.35 Max | 0.29-1.06 | 0.1 Min | 0.035 Max | 0.035 Max |

22-Write down the chemical composition of Carbon steel Pipes?

| Steel Grade | C% | Mn% | Si% | S% | P% |

| PA | 0.25 Max | 0.27-0.93 | 0.1 Min | 0.035 Max | 0.035 Max |

| PB | 0.30 Max | 0.29-1.06 | 0.1 Min | 0.035 Max | 0.035 Max |

| PC | 0.35 Max | 0.29-1.06 | 0.1 Min | 0.035 Max | 0.035 Max |

23-What is process of heat treatment is being followed in carbon steel pipes and tubes?

Generally Hot finished tubes & pipes need not be heat treated, cold drawn tubes or pipes should be given a sub critical annealing, a full anneal or normalising after the final cold finishing process

24-How many numbers of tests are carried out on carbon steel as per IBR regulations?

AS per IBR regulation No.37 (Carbon steel tubes), 43 (Carbon steel pipes) & 48 (Ferritic or Austenitic alloy steel) ,tests shall be made on minimum 2 tubes/pipes for first 100 and 1 per 100 over 100 Nos

25-Write down the required Tensile strength and Yield strength of seamless Carbon steel tubes & pipes as per regulation-38 & 44 respectively (Design metal temperature < 454 deg C)

Minimum required Tensile & Yield strength for Tubes-Regulation-38

| SL No. | Grade | Yield strength Mpa | Tensile strength Mpa |

| 1 | TA | 180 | 325 |

| 2 | TB | 255 | 415 |

| 3 | TC | 275 | 485 |

Minimum required Tensile & Yield strength for Pipes-Regulation-44

| SL No. | Grade | Yield strength Mpa | Tensile strength Mpa |

| 1 | PA | 205 | 330 |

| 2 | PB | 240 | 415 |

| 3 | PC | 275 | 485 |

Note: Desired Tensile strength of Tubes/pipes is always more than Yield strength

26-How do you calculate the Hydraulic test for tubes?

As per the IBR-regulation No. 42, each tube shall be tested by manufacturer at a pressure of one & half times the design pressure.

Hydraulic test for Tubes should be more than the pressure calculated from the per below formula;

P = 2St / D

Where =Test pressure

D = Outside diameter of the Tube

T = Wall thickness of the tube

S = Stress, which shall be taken as 40% of minimum tensile strength at room temperature

27-What is the Design metal temperatures of T1 & T2 alloy steel materials?

Design temperature of T1 & T2 alloy steel is 538 deg C

28- What is the Design metal temperatures of T5,T9, T11, T12, T91 alloy steel materials?

Design metal temperatures of T5,T9, T11, T12, T91 alloy steel materials is 649 deg C

29- What is the Design metal temperatures TP 304, TP 310 S, TP 316,, TP 316 H, TP 321, P 347 Austenitic alloy steel materials?

the Design metal temperatures TP 304, TP 310 S, TP 316,, TP 316 H, TP 321, P 347 Austenitic alloy steel materials is 816 deg C

30-Explain the heat treatment process for carbon steel, Ferritic alloy steel & Austenitic alloy steel materials

| Sl No. | Materials (Tubes) | Heat treatment process |

| 1 | Seamless Carbon steel | Hot finished pipes are not needed for heat treatment whereas cold drawn pipes should be given sub critical and full annealing followed by normalising |

| 2 | Ferritic alloy steel T1, T2, T5, T9, T11, T12 | Reheated and furnished in full annealed, isothermal annealed or normalised & tempered condition. The minimum temperature for Grade T1 & T11 shall be 650 deg C. The minimum temperature for Grade T5,T9 & T22 shall be 675 deg C. |

| 3 | Grade T91 | Shall be normalised at 1040 deg C min. and tempered at 730 deg C as final heat treatment |

| 4 | TP 304H, TP316H-Cold worked | Heat treatment at temperature 1040 deg C & 1100 deg C for 321 H & TP 347 H steels |

31-What are the major alloying elements added in T22 & T91 materials?

Major alloying elements are Chromium, Vanadium, Molybdenum and Nickel.

Generally, Nickel is not used in T11, T22 & T91 grades

32-What is the Maximum percentage of Chromium used in T91 grade alloy steels?

It is 9.5%

33-In which Ferritic alloy steels Vanadium alloying element is used?

Vanadium is used in Ferritic alloy steels of grade T91 & 20CrMoV121 alloy steels

34-In which Ferritic alloy steels Nickel alloying element is used?

Nickel is used in 20CrMoV121 alloy steels

35- Write down the required/allowable Tensile strength and Yield strength of alloy steels

Minimum required Tensile & Yield strength for Pipes-Regulation-44

| SL No. | Grade | Yield strength Mpa | Tensile strength Mpa |

| 1 | PA | 205 | 330 |

| 2 | PB | 240 | 415 |

| 3 | PC | 275 | 485 |

36-What is the size of filler rod used for gas welding of pressure parts as per regulation 98A

The size of the filler rod should be 1.6 mm

37-What is the chemical composition of filler rods for carbon steel material Grade-I?

Chemical composition of filler rods for carbon steel material-Grade-I

Carbon-Max-0.1%

Manganese-Max-0.6%

Nickel Max-0.25%

Sulphur Max-0.05%

Phosphorous Max-0.05%

Application: Used where, the minimum but weld strength is 35 kg/sq.meter of 22 MT/Sq.inch

38-What is the chemical composition of filler rods for carbon steel material Grade-II?

Chemical composition of filler rods for carbon steel material-Grade-II

Carbon-Max-0.15%

Manganese- 1 to 1.6%

Silicon-0.1 to 0.35%

Sulphur Max-0.04%

Phosphorous Max-0.04%

Application: Used where, the minimum but weld strength is 44 kg/sq.meter of 28 MT/Sq.inch

39-What is the chemical composition of filler rods for Carbon-Molybdenum steel composition?

Chemical composition of filler rods for carbon steel material-Grade-II

Carbon-Max-0.15%

Manganese-Max- 0.6 to 1.5%

Silicon-0.25 to 0.5%

Sulphur Max-0.04%

Phosphorous Max-0.04%

Molybdenum-0.45 to 0.65%

Chromium & Nickel-< 0.2%

Application: Used where, the minimum but weld strength is 44 kg/sq.meter of 28 MT/Sq.inch

40-How do the Boiler inspection fees are calculated?

Boiler inspection fees depends on Boiler rating, that is heating surface of the Boilers. Higher the heating surface more will be the inspection fees and Vice-Versa.

Heating surface of the boiler is nothing but the area which is exposed to flue gas.

41-What is the maximum allowable metal temperature for Water wall tubes, economiser tubes, convection super hater tubes and radiant super heater tubes?

1-Water wall tubes metal temperature: Saturation Temperature of steam + 28 Deg C

2- Economiser tubes metal temperature: Maximum designed water temperature + 11 Deg C

3-Convection super heater tubes metal temperature: Maximum designed steam temperature + 39 Deg C.

4-Radiant super heater tubes metal temperature: Maximum designed steam temperature + 50 Deg C

42-What is the maximum metal temperature of P-91 materials?

Maximum metal temperature of P-91 materials: 648 deg C

43-What is the minimum length of visible portion of a gauge glass?

Minimum length of visible portion of a gauge glass is 200 mm

44-What is the recommended size of Boiler gauge glass?

Recommended size of Boiler gauge glass is ½” to ¾”

What is the minimum recommended size of drain valves used for Boiler Gauge glass?

Minimum bore of valve used for Boiler Gauge glass is 1”

45-What is the recommended temperature of water being used for Hydraulic test?

Water temperature used for Boiler Hydraulic test should be 20 deg C to 50 Deg C

46-What is the allowable metal temperature of water wall headers?

Allowable maximum temperature of water wall headers is : Saturation temperature corresponding to the working pressure + 28 Deg C

47-When do you recommend for post bend heat treatment to bends?

If the bend thinning is > 25% of straight tube thickness, then it is eligible for post bend heat treatment

48-What is the minimum and maximum seat diameter of safety valve for small industrial Boilers?

Minimum and maximum diameter of safety valve sheet is 19 mm and 4.5” respectively.

49-What is the recommended thickness for Carbon steel pipes for stress relieving?

Minimum thickness for Carbon steel pipes for stress relieving is 20 mm and carbon % is > 0.25%

50-What is the Phenomenon of Fretting in Boiler Tubes failure?

Boiler tubes failure due to rubbing action is called Fretting

51-At what temperature generally the stress relieving (SR) is carried out?

Stress relieving of metals carried out below their lower critical temperature

52-When do Boiler feed pumps require two independent power supply sources?

If Boiler heating surface exceeds 102 M2, then Boiler feed pumps require two independent power supply sources.

53-Which boilers must be equipped with automatic water level control and alarms?

As per IBR Boiler capacity exceeding 3.7 TPH should have automatic level control and alarms provisions.

54-What is the recommended feed water temperature at economiser inlet?

Feed water temperature at economiser inlet should be more than 37.8 deg C

55-In which part of the sub critical Boiler do you observe maximum pressure?

In steam drums there will be maximum pressure as compared to other parts of the Boiler except feed water lines.

56-What is the periodic inspection frequency for welding electrodes?

Welding electrodes should be inspected at every 6 months.

57-What is the maximum period for engraving Boiler registration number after getting register number from inspecting authority?

It is within one month after the receipt of registration number

58-What is the maximum validity period of welding certificate issued by competent authority?

Its maximum 3 years

59-What is the minimum pressure holding time during Boiler Hydraulic tests?

Fr new Boilers pressure holding time is 30 minutes.

60-What is the circulation ratio of Once through Boilers?

Circulation ratio of Once through Boilers is unity.

61-Define Boiler as per IBR Act

Boiler is a pressure vessel in which steam is generated for itself or external use is wholly or partly under pressure.

62-What is meant by steam pipe?

The pipe through whci steam passes at pressure more than 3.5 kg/cm2 or pipe whose internal diameter is more than 254 mm and steam passing though it is more than 1 kg/cm2 pressure.

Reading this evokes the calm satisfaction of careful observation, noticing small, meaningful details and appreciating the rhythm of thought and reflection.